Mining

the mining industry depends on robust satellite connectivity

to optimize operations, monitor heavy machinery, and protect personnel.

For over 20 years, Ground Control has delivered advanced satellite IoT and asset tracking solutions,

ensuring seamless communication and operational efficiency anywhere on Earth and no matter how extreme the conditions.

Our Services for the Mining Industry

Enabling Remote Mining Operations with Satellite Connectivity

Global Coverage

Operating in some of the most remote locations on Earth, mining enterprises depend on reliable satellite connectivity to keep teams connected, ensure safety, and maintain peak equipment performance. We design and build satellite-enabled IoT and asset tracking hardware, partnering with trusted providers to deliver the right devices and airtime solutions for critical operations.

Rugged Tough Devices

In the harsh and demanding mining environment, equipment needs to be robust to withstand the conditions. Many of our devices are IP66 to IP68 rated and can operate across a wide variety of temperature fluctuations. We also build OEM devices that can be incorporated into existing equipment housing.

Remote Worker Safety

Our ruggedized RockSTAR devices keep remote workers safe, even in extreme weather and harsh, dusty conditions. With over 12 months of battery life, The RockSTAR leverages the global Iridium network for reliable two-way text communication, scheduled check-in requests, and one-touch SOS alerts in case of an emergency.

Tracking Platform

Cloudloop Tracking provides real-time monitoring of your entire mining operation, enhancing efficiency by tracking personnel, vehicles, and valuable specialist equipment through our cloud-based platform. For added flexibility, our APIs can integrate this data into your preferred mining operations management system.

Recommended Devices:

Remote Surveillance

How we support this sector

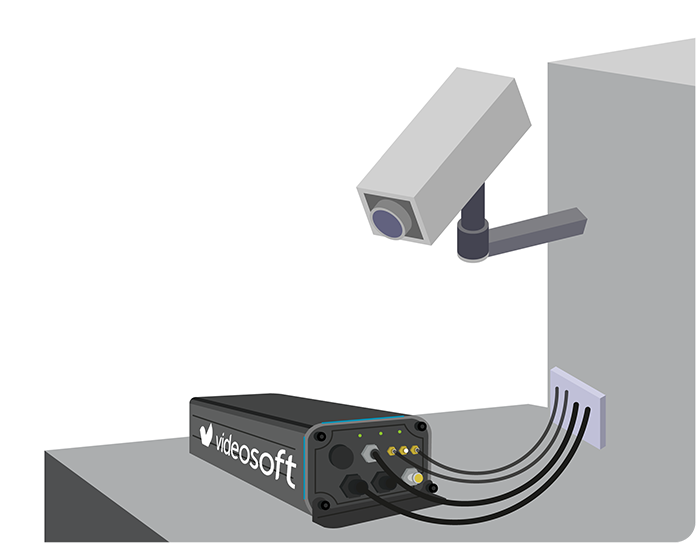

The RockREMOTE suite of products are capable of intelligently compressing data, providing an effective solution for surveillance applications in off-grid locations.RockREMOTE Rugged with Videosoft integration allows you to connect your smart camera via USB or IP, and experience cost-effective video transfer, enabling remote worksite video recordings and enhancing site security.

Alternatively, transmit compressed images through RockREMOTE Mini or Mini OEM.

Products to support this sector

Asset Management

How we support this sector

We offer a series of rugged devices for asset tracking in the harshest of environments and with minimal power draw, ensuring assets are constantly monitored.The RockFLEET and Iridium Edge Solar leverage the Iridium network, offering global pole-to-pole coverage with low latency.

The Orbcomm ST 6100 utilizes the Viasat satellite network of Geostationary satellites.

Products to support this sector

Monitoring Sensors

How we support this sector

RockBLOCK devices can transmit your important sensor data over the global Iridium satellite network, making them ideal for monitoring remote locations where cellular is unreliable or unavailable.The RockBLOCK 9603 can be incorporated into existing sensing equipment to provide satellite connectivity, or select the RockBLOCK Plus or RockBLOCK Sense which are designed to withstand harsh conditions, with dust and water ingression to IP68, and operating temperatures of minus 40C to plus 80C.

Products to support this sector

Worker Safety

How we support this sector

The RockSTAR is a rugged, tough device designed for teams working in remote locations. It enables two-way text communication, and features a dedicated SOS button and a 'check-in' countdown timer. The RockDASH is a carry-on, carry off device for drivers which transmits location and vehicle telemetry and offers two-way text communication and alert functions. Both Rock devices utilize the Iridium network and feature geofencing capabilities to keep teams and vehicles safe.The GSatSolar is a solar-powered, compact and lightweight tracker and can be easily attached to clothing. Built to withstand tough conditions, it can transmit location data continuously for months, even years, over the Globalstar network.

Products to support this sector

Who Uses Ground Control's Satellite Solutions for Mining?

Operations Managers

Ensuring effectiveness of the whole operation, our Cloudloop platform enables a holistic view of the mine using asset tracking and sensor data to ensure personnel, on-site facilities, vehicles and heavy machinery are operating safely, at maximum efficiency, to meet production goals.

Surveyors

UAVs equipped with video and imagery technologies can map and measure land to guide the development of the mine, as well as ensuring the mine's layout follows the plans. Using geological sensor data, surveyors can continuously monitor the impact of the mine development and adapt the plans if required.

Fleet Managers

Planning and managing vehicular routes and heavy machinery locations around the mine, as well as monitoring equipment regularly to prevent any breakdowns. Managing automation of site vehicle movements, especially in extremely cold mining sites, to increase operational safety.

Environmental Officers

Continuous monitoring of sensors within the tailings storage facilities and acid mine drainage to detect changes in volume, humidity, temperature, pressure and chemical compounds, and prevent the potential leaking of hazardous waste products into the wider environment.

Logistics Coordinators

Using asset trackers and telemetry sensors to record Mining Truck data, such as fuel levels and load weights, enabling ore collections to move from drilling site to trackside off-loading as efficiently as possible.

Heavy Equipment Managers

With specialist mining equipment working under extreme conditions, onboard sensors can detect excessive vibrations and measure hydraulic pressure, oil, fuel and engine temperature levels to manage the load of the machine and prevent unscheduled downtime which would affect the whole mining operation.

Health and Safety Officers

Ensuring all personnel are protected from the harsh environments of the mining operation whenever possible by using sensors to monitor air quality and initiating ventilation when required, ensuring heavy machinery operation is confined to dedicated areas with geo-fencing, detecting fatigue levels in staff and enabling teams to send messages in case of an emergency.

Satellite IoT & Tracking in Mining Applications

-

Unlocking Potential With Remote Video Surveillance

How remote video surveillance over satellite can prevent solar panel & asset theft, provide border surveillance, & prevent illegal activities.

Read more -

Satellite asset tracking for construction projects

Asset tracking is key to the construction industry, from preventing theft through to improving worker safety; and satellite is key to achieving these goals in remote construction sites.

Read more -

Infographic: How to unlimit your IoT application with the RockREMOTE Rugged

Our infographic draws out some of the key benefits of the RockREMOTE Rugged, leveraging LTE, Iridium Certus 100 and Iridium Messaging Transport, for flexible remote IoT connectivity.

Read more -

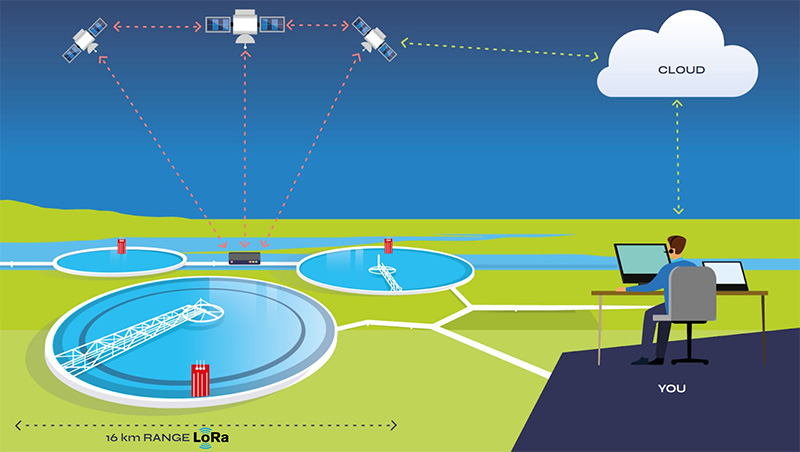

LoRaWAN Data Backhaul Using Satellite Connectivity

When LoRaWAN is a good choice for your IoT device wireless network, and how LoRaWAN and satellite connectivity can work together to maximise coverage, connectivity, and cost control.

Read more

Satellite Connectivity for Mining Operations

Equip your mining machinery and facilities with reliable, rugged tough satellite IoT and asset tracking devices, paired with competitive airtime plans and our powerful IoT platform, Cloudloop. Stay connected and informed with real-time data, whether working on-site in remote mining locations or managing operations from a central base.

Contact our team today to explore how our satellite connectivity solutions can improve the efficiency of your mining operations.